Precision in every process, excellence in every product.

Introduction

SERVICES

• Steel and mechanical engineering

• Tool and mold making

• Components and prototyping

• CAD constructing

• Transportation

WELTECH - Your reliable partner in the field of procurement and mechanical processing of various metals and plastic.

We specialize in the entire process from CAD constructing, developing smaller parts, creating assemblies, to developing

fully motorized machines by your wish and needs.

METHODS

• Welding

• CNC turning

• CNC milling

• Laser cutting

• Erosion

• Wire cutting

• Sanding

• Surface treatments

• Quality control

MATERIALS

• Steel

• Stainless steel

• Aluminum

• Bronze

• Brass

• Plastic

Constructing

Uppon recieving the inquiry our CAD

specialists carefully examine each CAD

draft provided by our customers.

Before the production starts we are in a

close exchange with our clients in regards

to any changes done to the product

drawings to achieve its full accuracy.

STEP 1

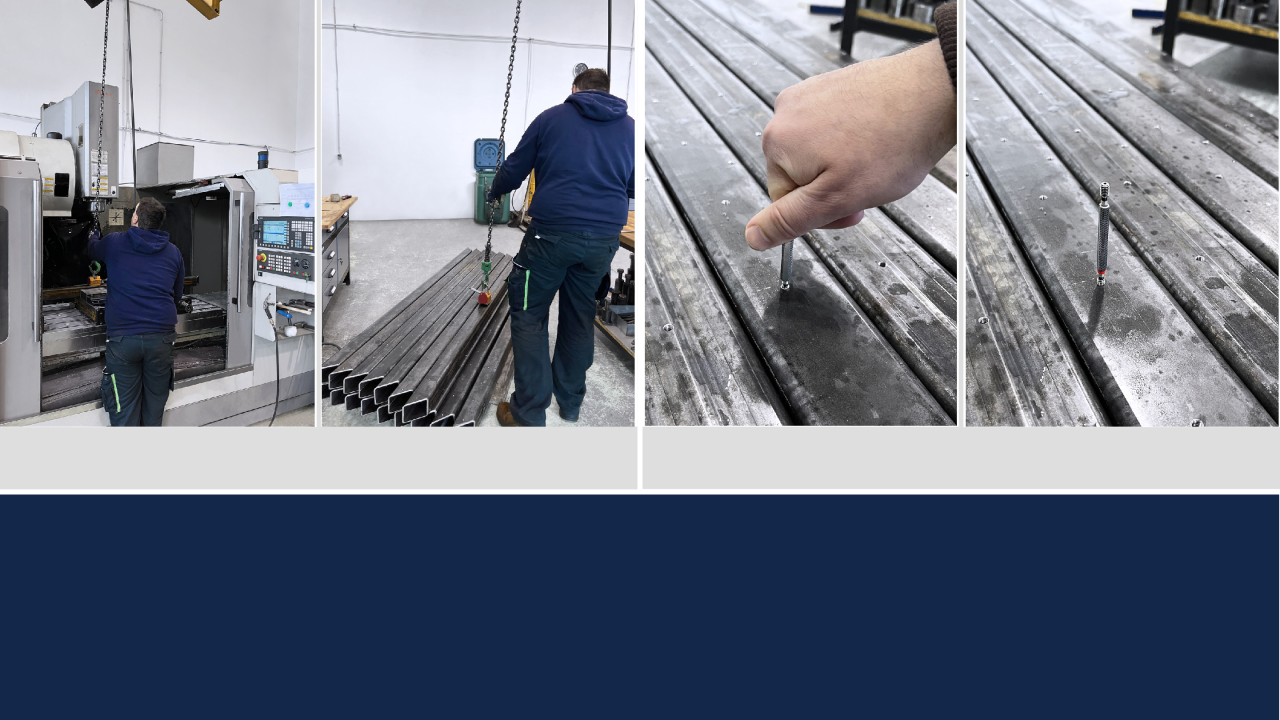

Preparing mechanical treatments

Finished CAD drafts are placed for machine

programing of either CNC milling or lathe machines.

The simmulations of the treatments are being ran to

assure correct results.

Simulation coding

Any changes are written in coding spreads.

All processes are examined and approved by

our specialists.

Detail inspection

Examining therefore possible

treatment results and details on

the processed product.

Pre production

preparations

Machine treatment preparation.

STEP 2

Pre production preparations

From 3D scanning, regulations and tools..

Pre production preparations

Everything for machine operating; Selecting from the storage of delicate to large tools.

Milling machine

Microcut RH-35

Milling machine

Microcut RH-35

Table movements:

X = 2000mm

Y = 840 mm

Z = 710 mm

Tool holder: BT 40

Maximum weight of the position: 1800kg

Finished pieces are removed from the machine with the help of a crane. Followed by exemination of the quality and acuracy on the spot.

Production flow

Milling machine | Microcut RH-35

CNC milling

machine

Microcut M1050

CNC milling

machine

Microcut M1050

Table movements:

X = 760 mm

Y = 850 mm

Z = 840 mm

Tool holder: SK40

Maximum weight of the position: 1000kg

Production flow

Workfow is being programed and

monitored throughout the entire

process.

Wide range of tool options for a desired processing method.

Milling machine | Microcut M1050

Production flow

Accuracy testing done extra during the production to ensure the quality.

Milling machine | Microcut M1050

CNC lathe machine

Microcut 52HTL

CNC lathe machine

Microcut 52HTL

Maximum position diameter: 450 mm

Maximum weight of the position: 500 kg

Raw material to processed products.

Production flow

Transparency of work.

The production is ready programmed, yet for each product CAD drawings

along side other required documentation is present in the production plant.

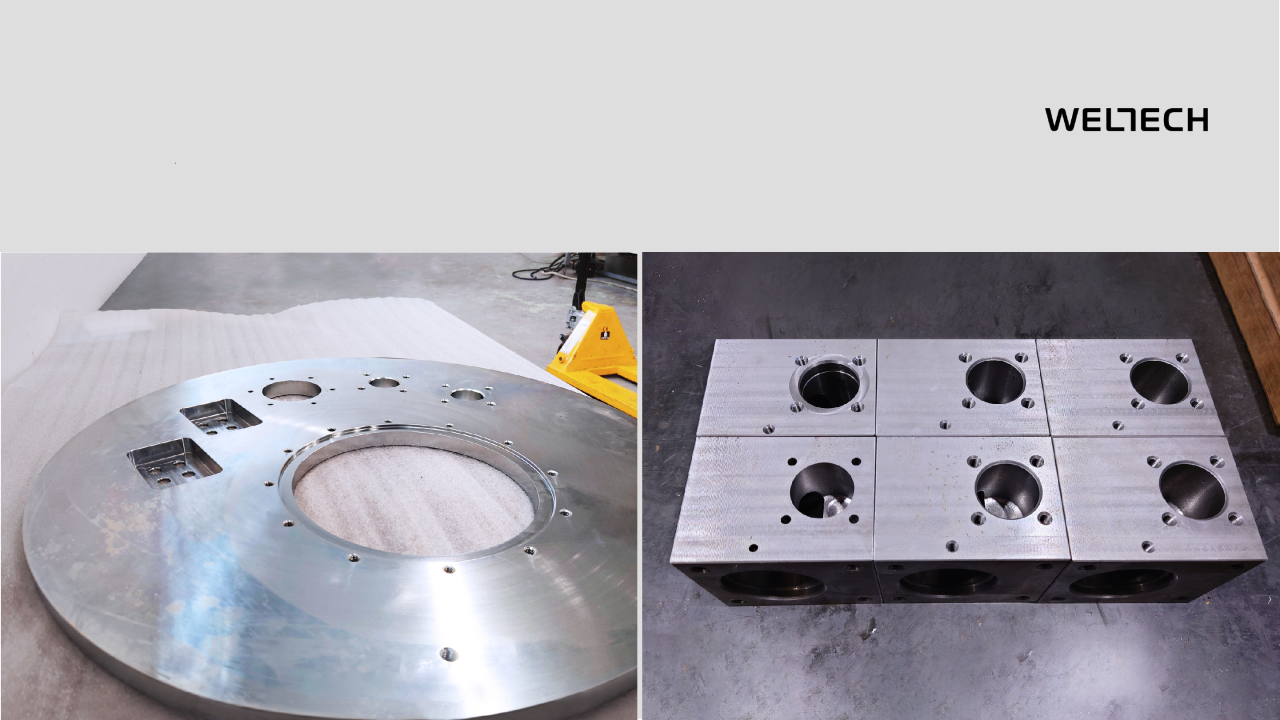

Finished products

An overview of some of our work.

STEP 4

Finished products

Percision and attention to every detail during the production results in percise finished products.

Finished products

Each piece is treated with extra attention, stored carefully for preservation of its quality.

Finished products

We strive to provide you with best outcome regardless of material type.

Finished products

From smallest to biggest products, regardless of material type we take pride in its accuracy.

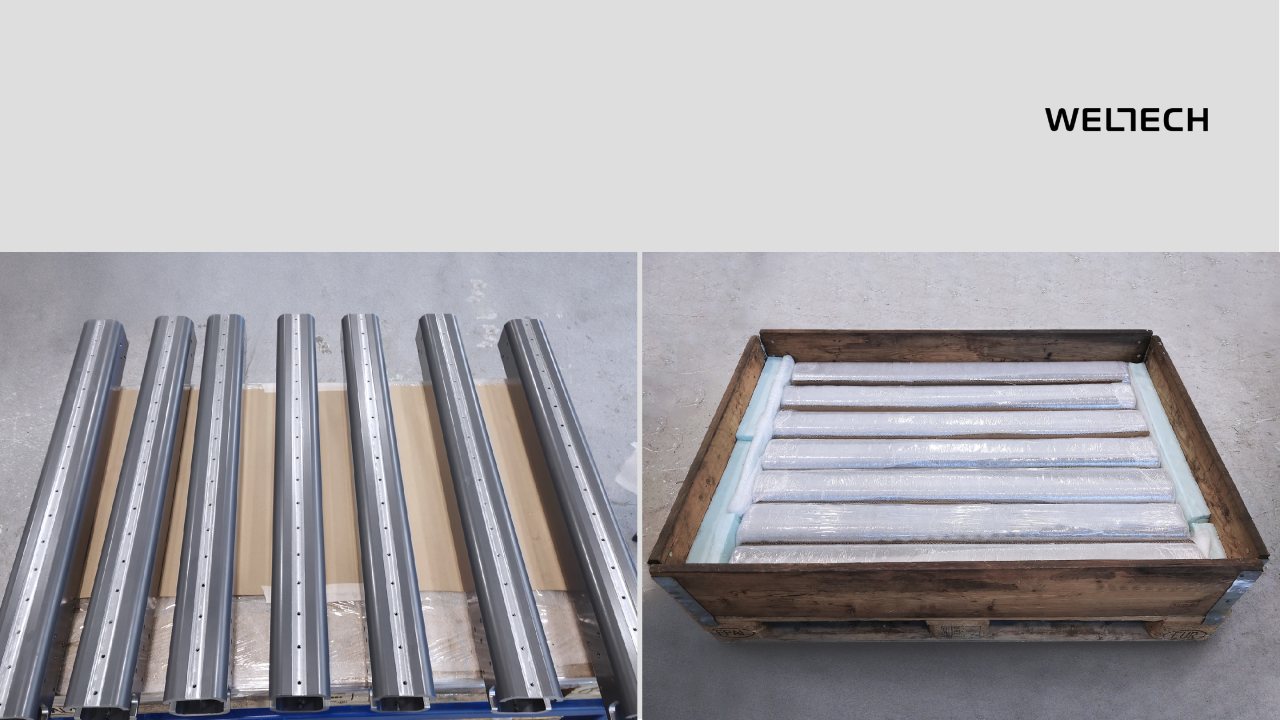

Careful individual packing in stretch foil.Clean finished product as a result of the final step

in the production.

Safely packed product ready for transport.

Product packing

All of our finished products are carefully treated until transported to our customers.

STEP 4

Product packing

Special care is set on metal goods. All in order to perserve surface treatment quality.

Product packing

We pack in foil, foam wrap or\and bubble wrap based on requirements.

Product packing

Even the smallest plastic pieces are packed individually.

Product packing

Even the smallest plastic pieces are packed individually.

Address

Kućanmarofska 24

42000 Varaždin, Croatia

Tel

00385 98 1747 575

Email Address

info@weltech.hr

Contact